Sector Analysis of Industrial Energy

Sector Analysis of Industrial Energy

Main findings

»» Reducing industrial energy demand could make a substantial contribution towards the UK Government’s goal of significant (80%) decarbonisation by 2050, whilst simultaneously improving productivity and creating employment opportunities.

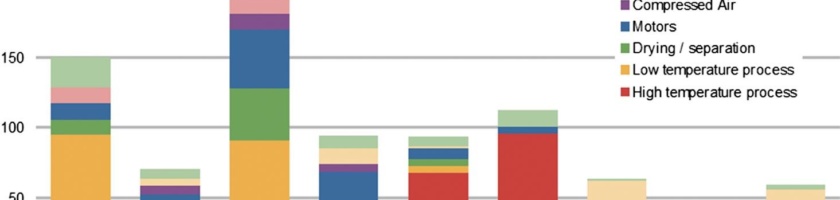

»» The industrial sector in the UK accounts for some 21% of total delivered energy and 29% of CO2 emissions. Three sectors make up 50% of industrial emissions; Steel, Chemicals, and Cement.

»» Efficiency gains can be readily secured in industry, including those associated with the use of heat and with improvements in processing.

»» A set of selected ‘technology roadmaps’ have been developed in order to evaluate the potential deployment of the identified enabling technologies for the UK energy-intensive industries out to 2050.