CIE-MAP Evaluates the Potential for Industrial Energy Demand Reduction and Decarbonisation in the Chemicals Sector

Chemicals are a complex collection of many diverse and interacting sub-sectors covering a wide range of feedstocks, processes and products. It can be characterised as being heterogeneous; embracing a diverse range of products (including advanced materials, cleaning fluids, composites, dyes, paints, pharmaceuticals, plastics, and surfactants). Physical outputs are moved around on an international scale within or between major companies that are truly multi-national. The industry is also highly focused on private R&D and protective of information, meaning that data availability is particularly poor. This high technology sector takes full advantage to modern developments in electronics and information and communications technology (ICT), such as for the automatic control of chemical process plants and automation in the use of analytical instruments. The scale of operation of chemical firms range from quite small plants (of a few tonnes per year) in the fine chemicals area, where high purity is required, to giant ones in the petrochemical sector. Batch production is employed by SMEs where small quantities of chemicals (up to around 100 tonnes per annum) are required. In contrast, continuous plants are typically used in cases where a single output, or related group of products, are demanded with plants of several thousands to millions of tonnes per year. They often produce intermediates which are converted via downstream processing into a wide range of products, such as benzene, toluene and xylenes (BTX), ethylene, phenol, and PVC from petrochemical refineries or via ammonia plants. Overall, the chemicals sector gives rise to the highest industrial energy consumption; mainly due to low temperature heat processes (30%), electrical motors (19%), drying/separation processes (16%), and high temperature heat processes (11%). It accounts for some 19% of GHG emissions from UK industry – the second largest sector after steel.

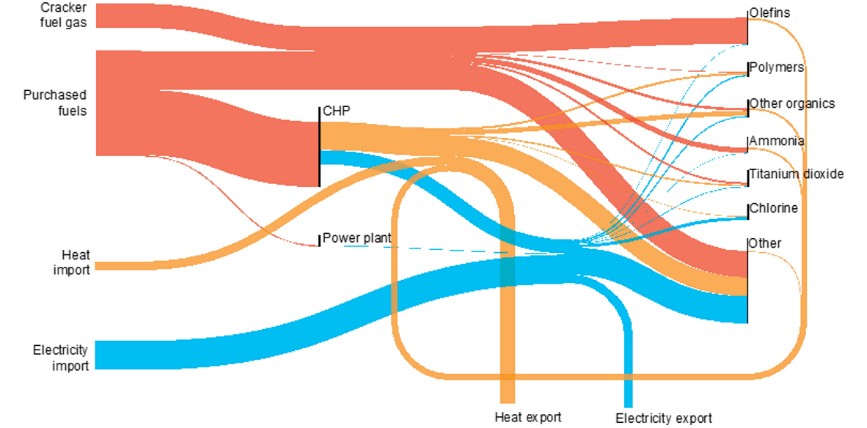

This strategically important sector for the UK has been studied by CIE-MAP researchers at the University of Bath (Geoff Hammond and Jonathan Norman, along with former PHD student Paul Griffin)*. They employed a Pareto-like approach in order to evaluate the opportunities and challenges of industrial energy demand reduction and decarbonisation in the chemicals industry [see the Sankey energy flow diagram below]. Sub-sectors that use a large amount of energy were prioritised via bottom-up studies, and emissions from those that could not easily be treated in this way were estimated via ‘cross-cutting’ technologies. The improvement potential of various technological interventions were identified, and currently-available best practice technologies were found to the potential for further, short-term energy and CO2 emissions savings in chemicals processing. But the prospects for the commercial exploitation of innovative technologies by mid-21st century are far more speculative. A set of industrial decarbonisation ‘technology roadmaps’ out to the 2050 were also developed, based on various alternative scenarios. These illustrated possible low-carbon transition pathways that represent future projections which match short-term (say out to 2035) and long-term (2050) targets with specific technological solutions so as to meet the key energy and carbon saving goals. These roadmaps help identify the steps needed to be taken by industrialists, policy makers and other stakeholders in order to ensure the emissions reduction from the UK chemicals industry. The attainment of significant falls in carbon emissions over the period to mid-Century will depends critically on the adoption of a small number of key technologies [e.g., carbon capture and storage (CCS), energy efficiency techniques, and bioenergy], alongside a decarbonisation of the electricity supply.

* Griffin, P.W., G.P. Hammond and J.B. Norman, 2017. ‘Industrial energy use and carbon emissions reduction in the chemicals sector: A UK perspective’, Applied Energy: available online 12th August [DOI: 10.1016/j.apenergy.2017.08.010].